Our Guide to Countertops

When it comes to designing your kitchen or bathroom, one of the most important choices you’ll make is your countertop material. Each stone offers its own beauty, durability, and maintenance needs. To help you decide, here’s a breakdown of some of our most popular options!

Marble

Known for its timeless elegance, marble brings sophistication and natural beauty to any space. Its distinct veining patterns and luxurious finish make it a popular choice for countertops, vanities, and accent pieces. Ideal for those seeking a refined, classic look.

Best for: Classic, luxurious spaces.

Consider if: You don’t mind a little patina developing over time.

Quartzite

A naturally strong and stunning material, quartzite offers unparalleled durability and beauty. Its rich patterns and elegant color variations make it a versatile choice for countertops, backsplashes, and other surfaces that require both style and resilience.

Best for: Homeowners who want a durable, beautiful natural stone

Consider if: You’re drawn to unique, one-of-a-kind patterns.

Granite

Celebrated for its strength and natural beauty, granite is a classic choice for countertops and other stone surfaces. Its unique patterns and wide range of colors provide endless design possibilities, while its exceptional durability ensures it stands up to daily wear and tear for years to come.

Best for: A versatile, long-lasting countertop.

Consider if: You want to give new life to a material that’s stood the test of time

Quartz

Engineered for durability and versatility, quartz offers a wide range of colors and patterns to fit any design aesthetic. Its non-porous surface makes it highly resistant to stains and scratches, perfect for busy kitchens and bathrooms where performance matters.

Best for: Busy households that want beauty and easy upkeep.

Consider if: You like the look of man-made stone

Soapstone

Renowned for its smooth texture and rich, matte appearance, soapstone adds a distinctive charm to any space. Naturally heat and stain-resistant, it’s perfect for countertops and fireplace surrounds, offering lasting beauty with minimal maintenance.

Best for: High contrast or dark & moody spaces that still feel classic.

Consider if: You like a countertop that changes character over time.

Limestone

A naturally warm and inviting material, limestone offers a soft, earthy appeal perfect for countertops. Its subtle hues and organic texture create a relaxed, timeless look that enhances both modern and traditional spaces. It is more porous than other stones, so it may need more careful maintenance.

Best for: Low-traffic areas or bathroom vanities.

Consider if: You want a soft, natural aesthetic and are willing to care for it.

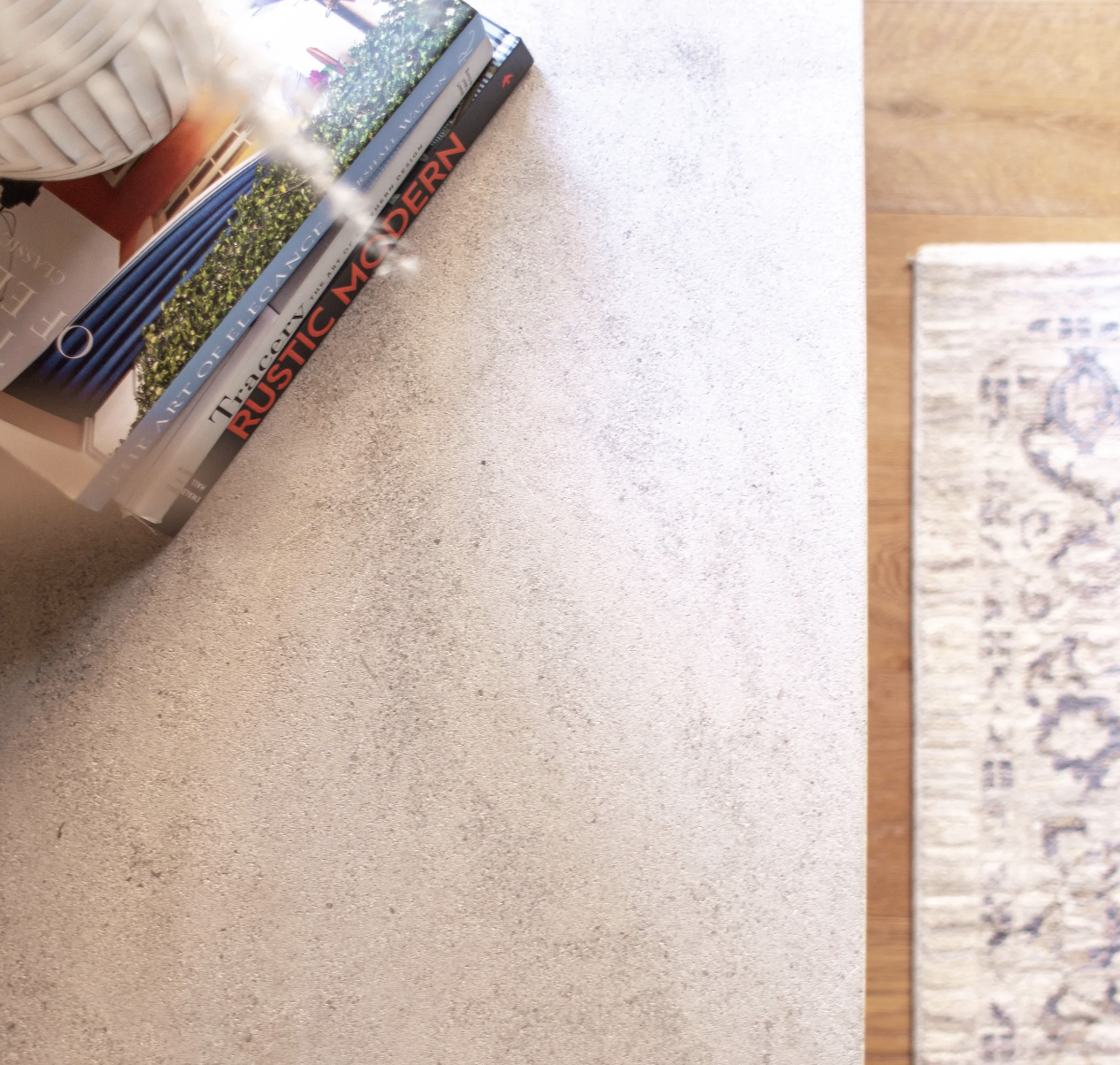

Choosing the Right Tile

It all begins with an idea.

Stone vs. Ceramic vs. Porcelain

Choosing tile for your home can be an overwhelming process. There are so many different types and styles that it can be hard to know where to start. Here is a brief overview of the differences between stone, porcelain, and ceramic tile that will hopefully give you a good starting point when making your selections!

S T O N E

Stone tile can tolerate heavy foot traffic, doesn't attract dust, and creates a naturally elegant look. While natural stone tile is often the most expensive option and can be more likely to get scratched, it can add significant value to your home. There are many different types of stone tile, like marble, limestone, and more, that all have their own unique characteristics and advantages.

C E R A M I C

Ceramic tile is typically the most economical tile option. It is somewhat more susceptible to moisture infiltration, but as long as the face of the ceramic tile is glazed well and in good condition, it will resist water. Ceramic tile comes in many different shapes, colors, sheens and textures. We love a ceramic tile if you are looking for a more organic, handcrafted feel!

P O R C E L A I N

Porcelain tile is denser, heavier, and more impervious to water. It’s a great choice for indoor use as well as outdoor use in milder climates. If you are hoping for the look and feel of natural stone, but want something more cost-effective, porcelain tile is often made to look like marble or other natural stones and can be a great alternative.

T I L E S H O W R O O M S

We hope this gives you a good starting point for your tile selections! We also have an experienced team of tile experts at our Pelham, Tuscaloosa, Chelsea, and Downtown Birmingham locations who would love you help you select the perfect tile for your home. Feel free to stop by or contact us here to set up an appointment!

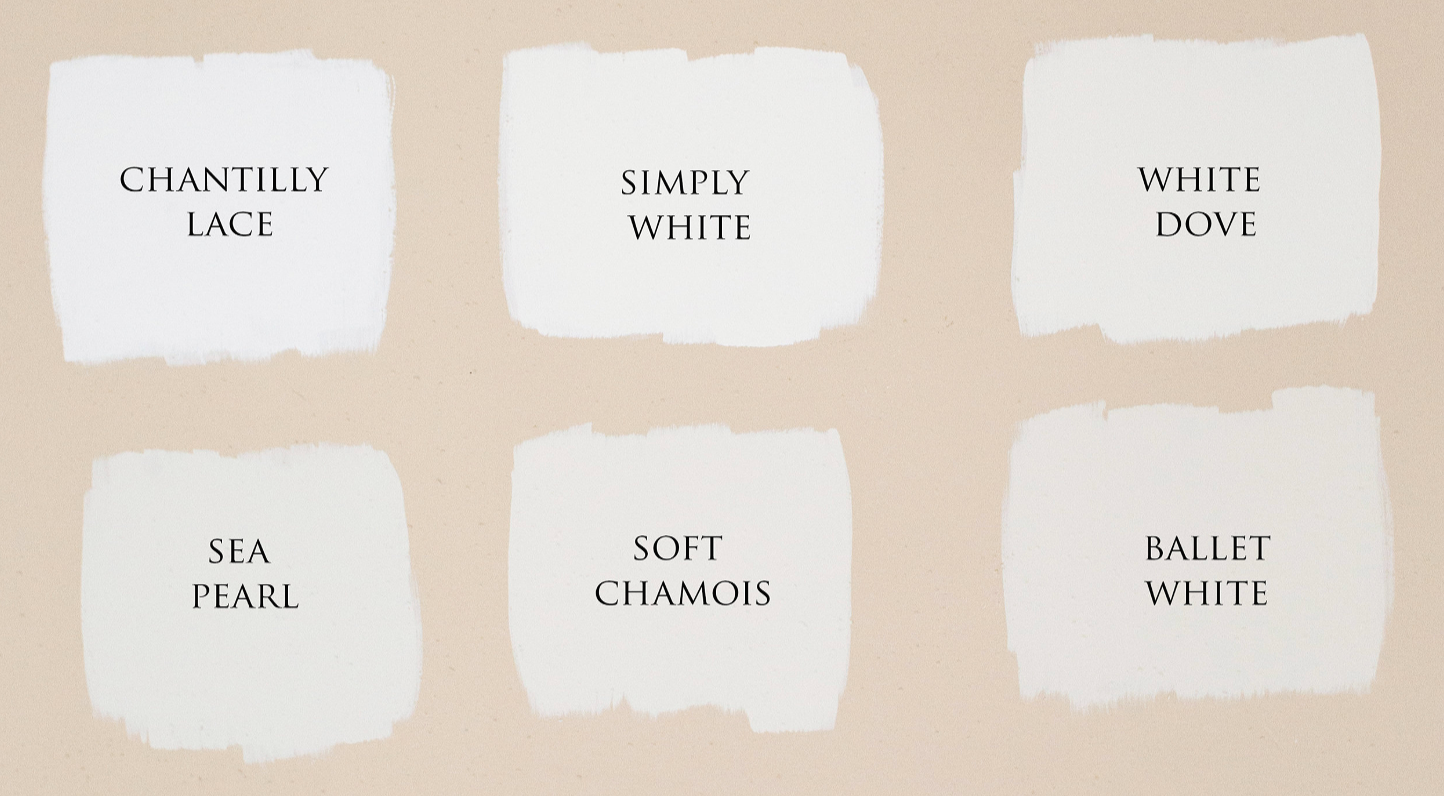

Our Favorite White Paint Colors

It all begins with an idea.

If you've followed along with us for a while, you may have noticed that we are big fans of white walls! While we do love many other colors, there is something special about starting with a blank canvas of bright, clean, white walls. Have you decided to try out the white wall trend but are feeling lost about which white to choose? Look no further! We've compiled our favorite and most popular whites and consulted one of our experts, Jill Campisi, on what makes each of them unique.

First up is Chantilly Lace OC-65. This timeless, true white is a favorite of ours because it is pure, clean and crisp. It's the ultimate blank canvas.

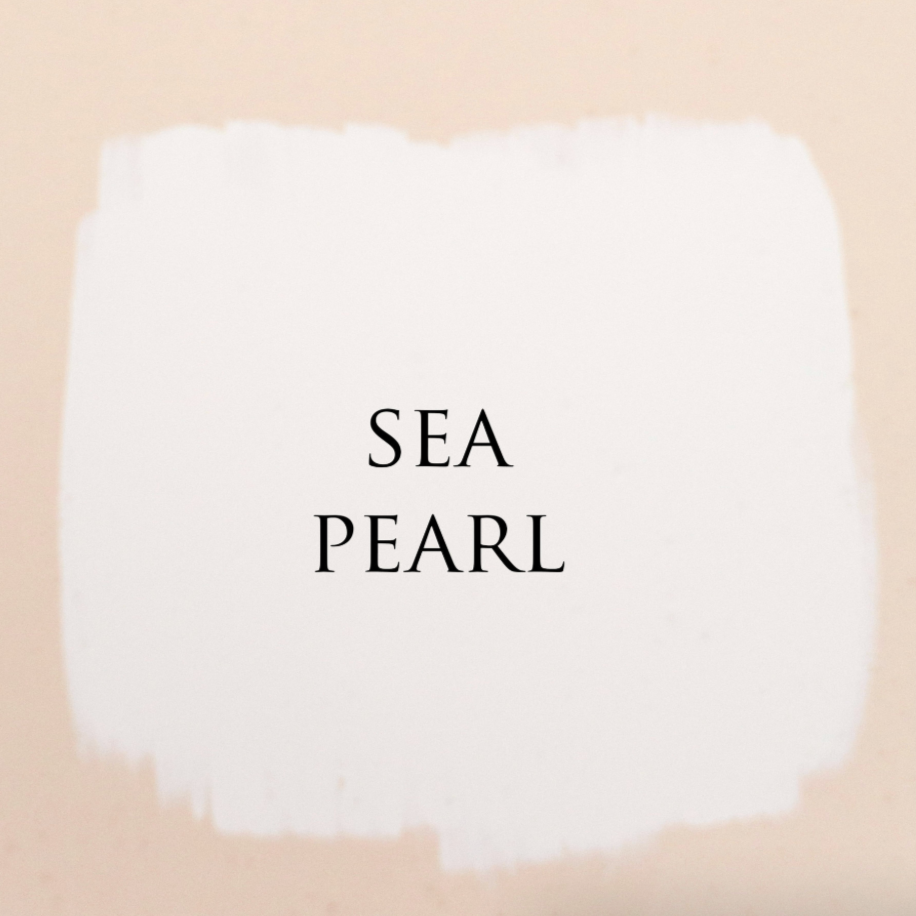

Sea Pearl OC-19, formerly known as China White, has creamy grey undertones that truly represent the characteristics of a pearl. It's soft and gentle and adds just enough warmth without being yellow. Sea Pearl pairs well with contrasting darker colors like Revere Pewter HC-172.

Simply White OC-117 is simple, just like it's name. It has a touch of warmth, but still remains a very clean, bright white. It was named Benjamin Moore's Color of the year in 2016.

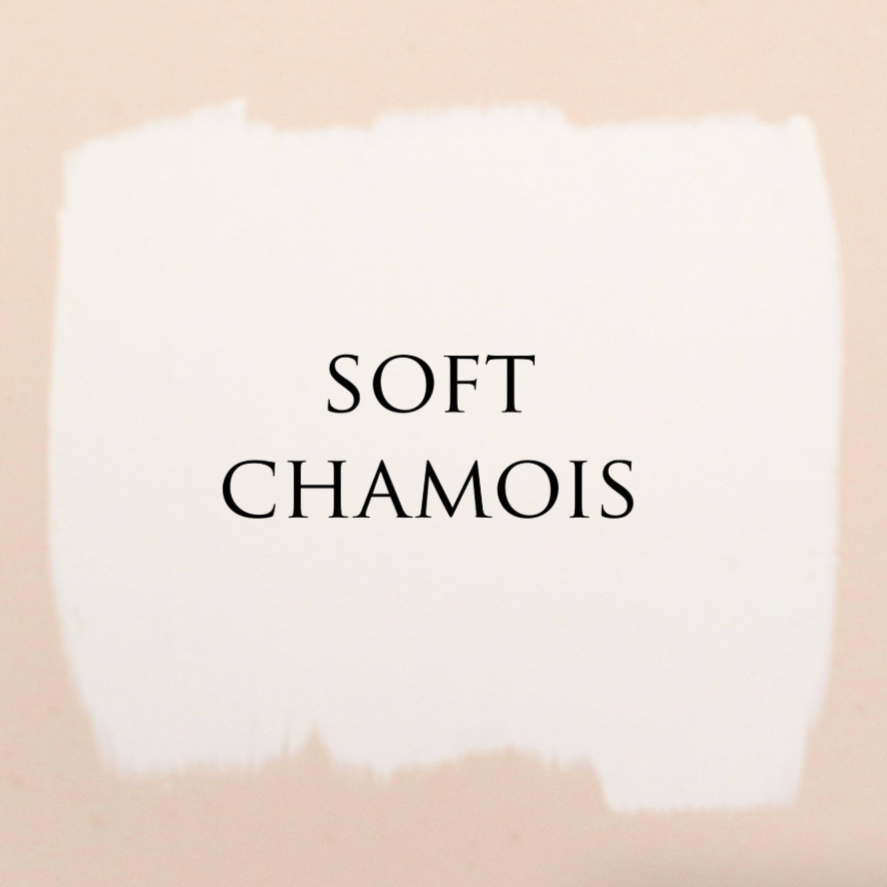

Soft Chamois OC-13 is one of the warmest whites listed here. It is as versatile as it is tranquil, and a great backdrop for richer accent colors in art, fabric, and accessories.

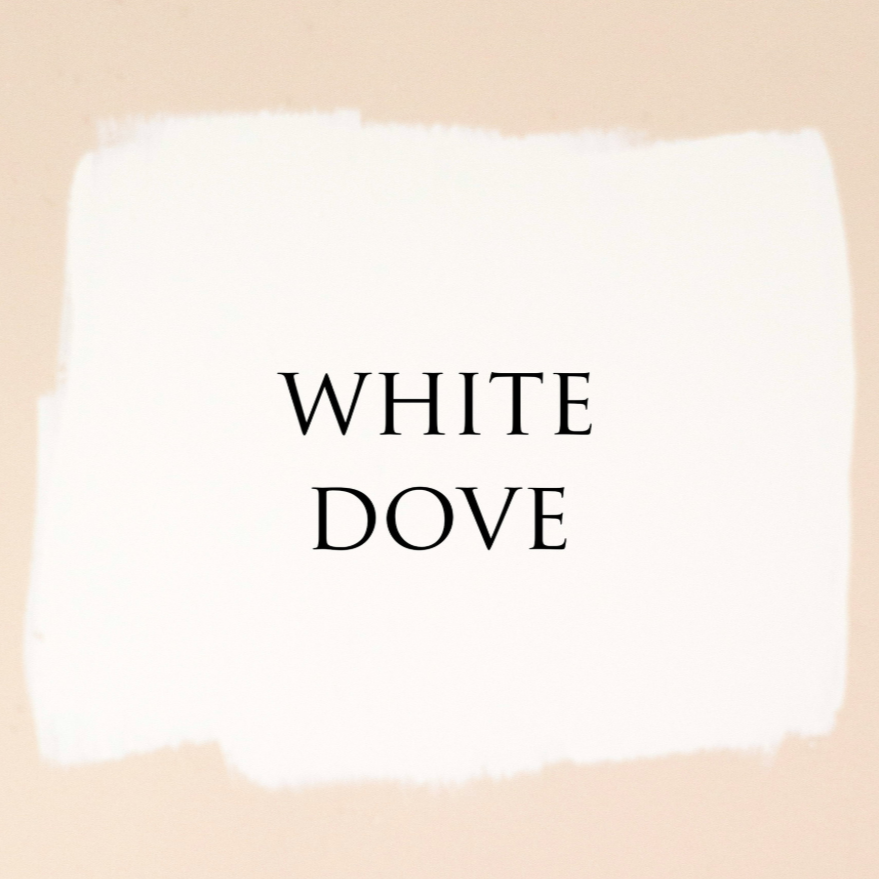

White Dove OC-17 is our go to white. It pairs well with almost any color. It looks very creamy on a swatch but is soft and warm on a wall, trim, or cabinets while still maintaining its claim to be a true white.

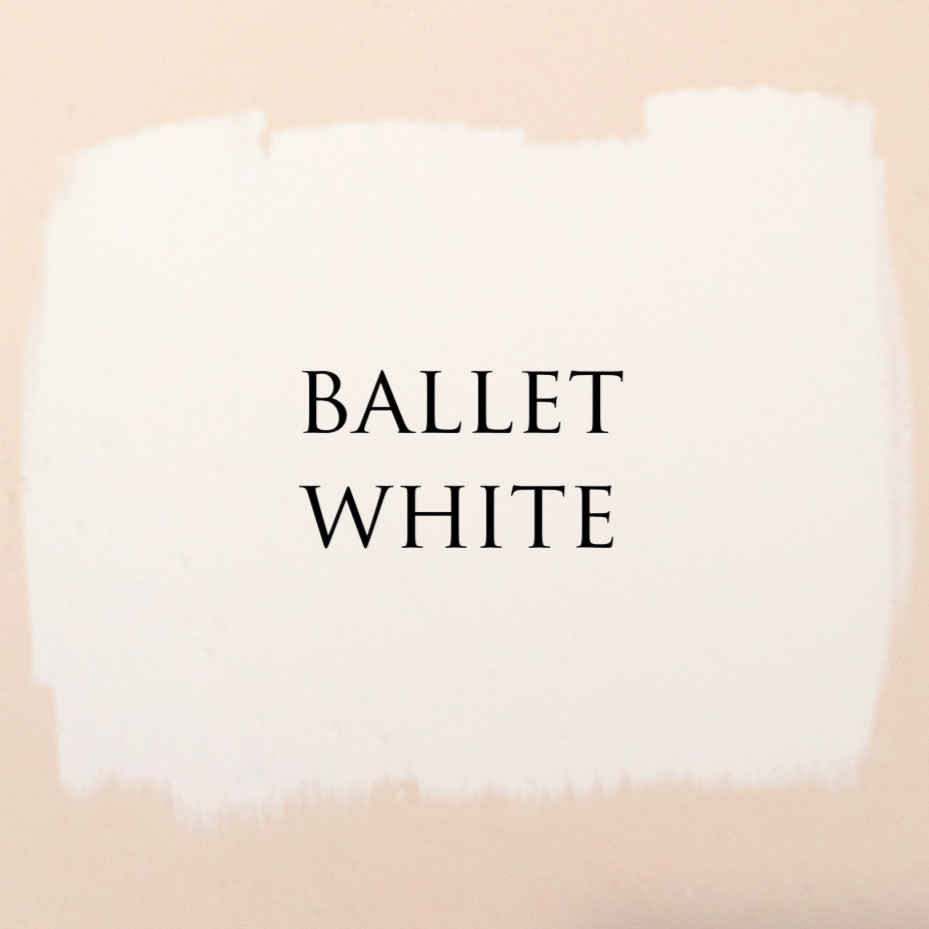

Lastly, we have Ballet White OC-9. This color is off white with a hint of beige. It's a very saturated white that will give your walls a slight pigment, especially if paired with a contrasting white trim.

Engineered Hardwood Flooring

It all begins with an idea.

Hardwood flooring has always been considered the cream of the crop as a residential flooring choice. It has the ability to give an elegant, timeless and natural look for your home. In more recent years, Engineered hardwood flooring has become increasingly popular as an alternative to traditional solid hardwood flooring. We’ll be sharing a few reasons why we love engineered hardwood flooring!

Let us first clarify that engineered hardwood is actually still wood. The “engineered” part is what lies beneath the top, thinner layer of hardwood… and even those under-layers are still, in fact, wood. Manufacturers utilize plywood to build up each plank to a typical thickness, and they lay them so that the direction of the grain alternates from layer to layer. The top layer is not plywood, but a thin layer of naturally beautiful oak or some other hardwood species.

Traditional hardwood, by contrast, is just one solid layer of wood all the way through. On the surface (pun intended), it might seem that this would always be the best option, but that’s not always the case. There are some advantages to engineered hardwood.

Engineered hardwood is prefinished. What does this mean? It means there’s no guessing when it comes to selecting exactly the color and finish you’re aiming for. It means a wide array of options from manufacturers who have spent time fine-tuning their stains and sheens. And perhaps best, it means that installation is the first and final step in the process. Unlike traditional hardwood – often referred to as “sand-and-finish” or “site-finished” hardwood – there’s no dusty sanding, no tenuous staining, no stinky sealing, and no waiting days and days for it to cure.

The resiliency of engineered wood often surpasses that of solid, traditional hardwood. Its layers of cross-grained plywood actually serve to fortify each plank, which makes them more resistant to the cupping and gapping that can occur with water damage or varying levels of humidity. This allows engineered wood to be installed in locations that solid wood would be ill-advised, such as the concrete substrate of a basement. The resilience of engineered wood also enables ultra-wide planks to be made that achieve a unique, high end look that will withstand the even more pronounced problems that moisture presents to wider cuts of solid wood.

The finish of engineered hardwood is harder and tougher. Think about a factory paint job on a vehicle as compared to a body shop paint job. After-market finishes never quite live up to the quality of the manufacturer’s. While site-finished flooring is at the mercy of the weather and conditions surrounding it (humidity, temperature, foot traffic from other tradespeople, etc.), flooring manufacturers use UV rays to bake on their finish in a controlled and consistent environment. They’re also able to use chemicals like aluminum oxide for a hardness and adherence that cannot be achieved on site.

Engineered wood is often more competitively priced than traditional sand-and-finish, solid hardwood. The elimination of installation steps along with the ability that manufacturers have to efficiently produce large volumes at a time usually lead to cost savings for homeowners.

Engineered hardwood comes in many shapes, sizes, and colors to fit any style. Stop by our Pelham, Hoover, Chelsea, or Tuscaloosa locations to see our selection of beautiful engineered hardwoods and get started on your next project!